This intricate field consolidates trend setting innovation, material science, and vital intending to beat the exceptional difficulties introduced by sea-going conditions. In this aide, we dive into the study of lowered structures, investigating key strategies, the impediments looked in building submerged, and the developments that are forming the eventual fate of submerged development.

Cofferdams are transitory nooks worked inside or across waterways to make dry work conditions by siphoning water out of the encased region. These nooks are commonly utilized for developing scaffold establishments or other lowered structures. Cofferdams are great for shallow waters however are less effective at more noteworthy profundities. Find out more information about kjerneboring.

There are different kinds of caissons, including open, pneumatic, and drifting. For instance, pneumatic caissons are compressed to permit laborers to work in dry circumstances while the construction stays submerged. This strategy is ordinarily utilized in the development of enormous starting points for extensions and wharfs. Find out more information about dykketjenester.

Building lowered structures requires specific methodologies because of the intrinsic trouble of working in wet, frequently low-perceivability conditions. Here are the essential methods used to develop submerged structures:

This procedure is fundamental for seaward designs like oil apparatuses and wind turbines. Heap driving is likewise utilized for submerged help structures for structures situated on or close to shorelines.

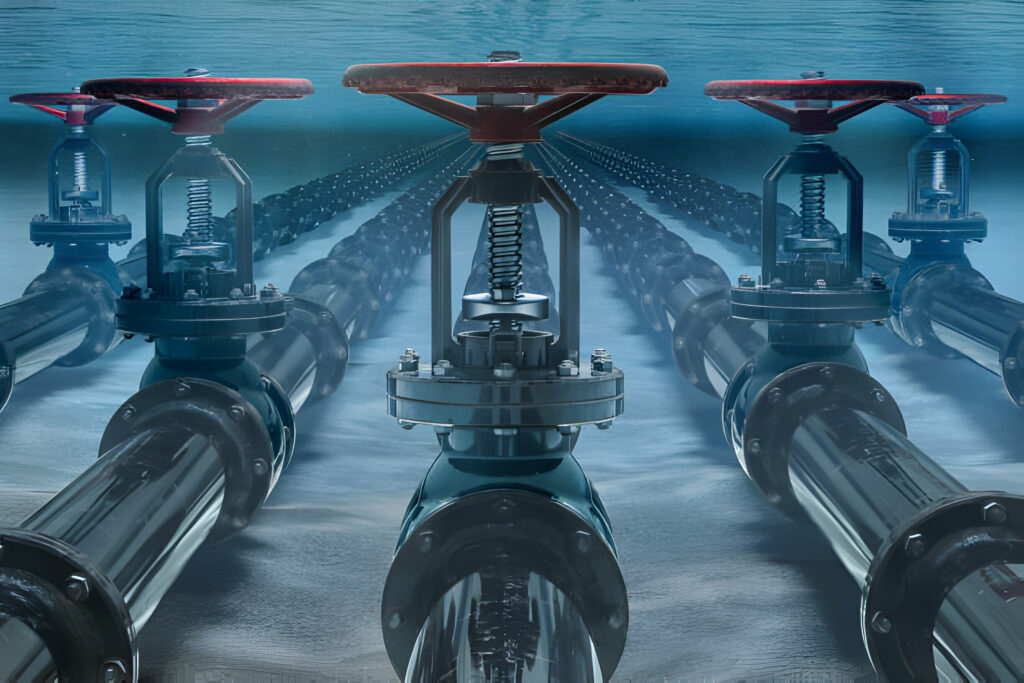

Heaps are long, thin sections of steel, cement, or wood that are crashed into the seabed to make stable establishments. Caissons are enormous, watertight boxes that are brought into position and sunk down to make submerged establishments.

This is particularly significant for submerged pipelines, ports, or designs worked in shallow water. Digging guarantees that the development region has a level and clean establishment.

Submerged welding, likewise called wet welding, is acted in water and includes unique procedures to deal with the dangers presented by electrical flows in a lowered climate.

Dry welding led in a fixed climate, is much of the time utilized in more profound waters to make more grounded, more solid welds. Digging is the most common way of eliminating residue, rocks, and other flotsam and jetsam from the seabed to get ready for development. Welding is fundamental for joining primary components in numerous submerged activities. Learn more details about Kristiansand Bygg AS.

As the profundity of development expands, the strain applied by the water turns into a critical test. Engineers should configuration designs and use materials fit for enduring the monstrous tension of profound waters.

Openness to saltwater speeds up erosion, which can debilitate structures over the long haul. Exceptional materials, coatings, and development procedures are expected to moderate the impacts of erosion and guarantee the drawn out strength of submerged structures.